It's Inauguration Day!

Congratulations, Matt vandenBerg, OWU's 17th President!

View details for Inauguration Day and stream the event live.

Congratulations, Matt vandenBerg, OWU's 17th President!

View details for Inauguration Day and stream the event live.

An OWU Information Services Success Story

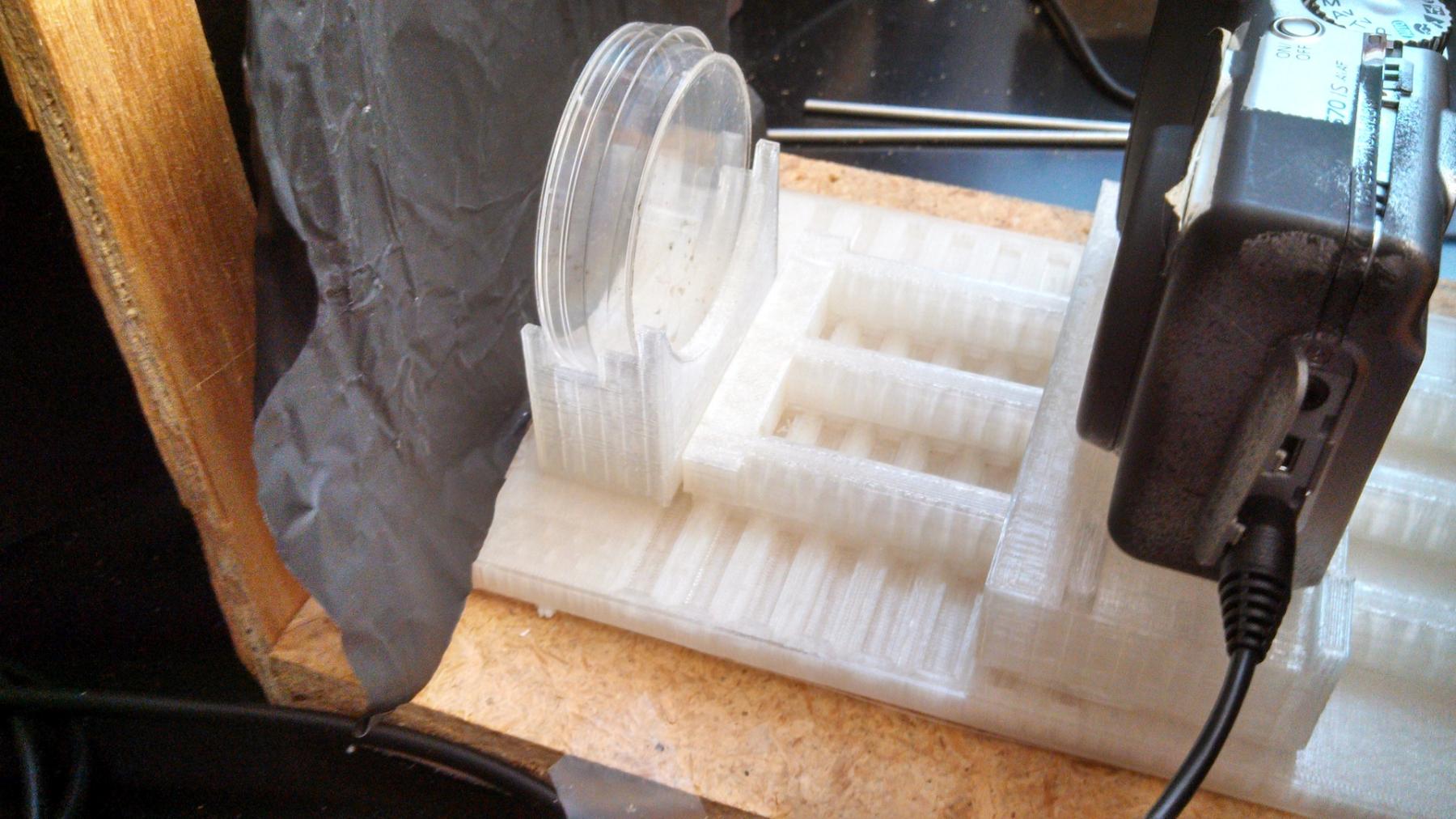

The OWU Department of Botany & Microbiology recently acquired a MakerBot Replicator 2 printer. For now, it’s being used to construct custom-made 3D pieces of equipment for research purposes.

The OWU Department of Botany & Microbiology recently acquired a MakerBot Replicator 2 printer. For now, it’s being used to construct custom-made 3D pieces of equipment for research purposes.

Professor Chris Wolverton and Information Services arranged for the printer’s purchase, and Wolverton coordinates its use in his teaching lab. He calls it “a prototype builder” because it gives users a tactile appreciation of their research pieces and allows them to identify opportunities for improvement. Wolverton says the equipment his student is producing now with the 3D printer is not what Wolverton originally envisioned–it’s better.

Junior BOMI major Patrick Zmina quickly became the primary user of the printer and is happy to share what he’s picked up so far. He cautions, for example, that users can’t let the workstation go to sleep in the middle of a job, which can take several hours. If this happens, the printer still will be communicating with the computer, but it no longer will be functioning. Users could wind up with the start of a piece and a glob of plastic on top.

In addition, although many free designs are available with the software and online, Zmina has had to learn both Google SketchUp and MakerBot’s own MakerWare to build custom pieces for the labs. He knows these are marketable skills applicable to many careers, and he’s having fun.

As Wolverton described early on, he and Zmina started with a simple holder for an LED light. With that piece under their belts, they started a more significant project: “a tray that would hold a digital camera in exactly the right position to take photos of roots on a Petri dish.” And they have accomplished this, too, allowing them to precisely position not only the camera but the petri dish as well.

When building a piece, the printer first lays a thin plastic tray underneath the actual project. This is similar in purpose to the frames around model car pieces in boxed kits. The tray holds the project pieces in place and prevents them from sticking to the printing platform. A recent update to the MakerWare software has it building honeycomb patterns, more efficient than the previous squares, on the inside. This allows easier removal from the base.

Wolverton is promoting campus-wide adoption of the device, or more like it, and expects an iterative approach similar to the actual use of the printer itself.

“First, folks will have to hear about it to get them thinking about how they might use it,” he says. “Then they try it out and find what works and what doesn’t. Then they adapt that.”

Wolverton hasn’t fully explored the many educational uses for the 3D printer, but has several ideas. These include building 3D models of viral proteins to help students visualize them and to design models of their own.

Faculty interested in exploring how they might use the 3D printer are invited to contact David Soliday or Chris Wolverton for more information.

Faculty interested in exploring how they might use the 3D printer are invited to contact David Soliday or Chris Wolverton for more information.